NOTICE: Certain links on this post may earn a commission for Western Hunter Magazine from Amazon or our other affiliate partners when you make a purchase. Thank you for your support.

Guide to Buying Down Insulation

Hunting clothing, like most things these days, has come leaps and bounds in the last decade, benefiting from the influx of technology and advancements in manufacturing. I’ve been hunting my entire life but started hunting all over the West in 2012. My first backpack hunt in Nevada quickly taught me the importance of clothing when it comes to withstanding the elements. At the time I had no idea what I was doing, nor did I realize the access to the quality gear that I was about to have.

After 6+ years of working for a well-known hunting gear manufacturer, my knowledge of hunting clothing has come a long way since 2012 when I narrowly avoided hypothermia on my inaugural backcountry hunt in NV. I want to share some of this knowledge, particularly on down jackets, and provide some insight into what you should be looking for when doing your research before purchasing one.

Why Down?

One of the biggest questions out there when having the insulated jacket conversation is Down vs. Synthetic. Both have their place in a clothing system, but comparing the two is apples to oranges. Down is a better insulator, lighter weight, compresses smaller, and due to the down-proof coatings, the jackets are inherently more wind resistant. Synthetics have their own benefits, but that’s a topic for a different article.

If I were to be looking for a garment for the sole purpose of warmth, there would be no reason to look any further than down. Especially with all the new tech and quality standards that are being used nowadays. Before the introduction of technical clothing, it was rare for your everyday consumer to pay attention to specs like fill power, down to feather ratio, or DWR. Now that these terms are so commonly used around the industry, you may be asking yourself “what does it all mean?”

Fill Power

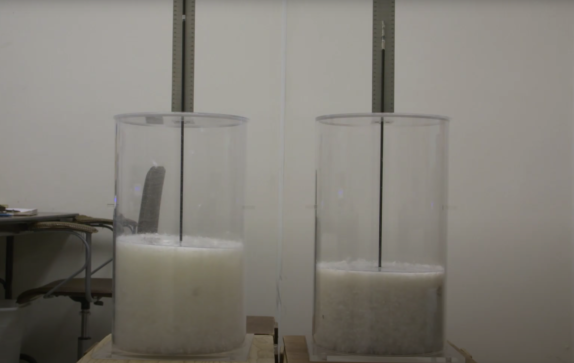

So what is Fill Power and why does it matter? Fill Power is a standardized measurement for the volume of down. To get it, testing facilities take 30 grams of clean down and put it into a volumetric cylinder. They then drop a precisely weighted plate on top of the down to compress the fill.

Once that plate comes to rest on the top of the down clusters, the fill power measurement is recorded as a volume. The higher the number (volume), the higher the quality of down. The highest fill power down on the market is between 900 - 1000.

So why should you care about that? It’s not to say you can’t get the same warmth out of a 650 fill power jacket as you can with an 850, it’s just going to take more down, be less compressible, and have a higher overall weight. A higher fill power achieves the same warmth as a lower fill power but requires less material to do so.

Down to Feather Ratio

One of the lesser-known specs of quality down is the down to feather ratio. In all down garments, there is a mixture of high-volume down clusters and regular feathers.

The clusters are what actually do the insulating, where feathers bring no insulating properties whatsoever. So why are feathers still in there? Other than it’s difficult to get them 100% removed, they add structure to the mixture which in turn helps the clusters hold their lofty structure while the garment is being worn.

This is another sign of quality. For example, Stone Glacier uses a 90:10 ratio in their down products. Any reputable down manufacturer will aim for a ratio of 90:10 to 95:5 so that the end product has as many insulating clusters as possible creating a warmer garment. So keep an eye on this, and if it’s not given by a manufacturer, don’t hesitate to ask.

DW What?

DWR - Durable Water Repellent. This treatment is now widely used across the majority of clothing products within the hunting industry. It’s on rain gear, soft-shells, fleece mid-layers, gloves, and even some hats. Another commonplace for a DWR coating to be used is IN and ON down garments. Not only are a majority of face fabrics treated, but the down itself is treated with a coating of DWR.

Here is why that is so important: Non-treated down can become useless once it is saturated with moisture. The moisture would collapse the structure of the clusters rendering their insulating properties to zero. This moisture doesn’t just come from precipitation, but also your perspiration from the inside of the jacket. By coating the face fabric with a DWR, it protects the down from external moisture to a certain point, but not enough to really make a difference when you truly need the warmth during a storm. The addition of a DWR to the down itself protects the entirety of your insulation. This is why a down jacket will make the cut for any hunt, no matter the conditions.

Face Fabric

One of the biggest misconceptions by consumers about down jackets is their durability. I have talked with countless people who express frustration when they rip or puncture the face fabric on their new expensive jacket. I am here to tell you that high quality down garments ARE NOT made with durability in mind. With down’s incredible warmth to weight ratio, it would go against the entire concept of a down garment to use a durable and heavy face fabric. That would take away the benefits we talked about earlier: lightweight, compressible.

Now with that said, there is a huge variety of face fabrics used, and their durability can be very different. So when you buy a new down garment, be smart about it, feel the fabric, and don’t fall prey to the word “durable” in the product description and end up being “That Guy” who is upset when you puncture a hole in your new $300 jacket.

Fit and Function

So how should it fit? Down garments should not be a tight-fitting piece, for multiple reasons. First of all, down doesn’t perform to its potential when compressed, and your body heat will actually make the arms of the clusters stretch out and stiffen up to increase volume and therefore insulate better. A tight-fitting jacket or pant will restrict the space needed for the fill to fully “puff up”.

Second, you need to be able to wear multiple layers underneath. These are pieces designed to keep you warm in cold weather, and the colder it is the more layers you will have on. So, when spending the exorbitant yet worthwhile price on a down jacket, try it on with all your other layers before throwing it in your pack. Most companies don’t let you return it dirty.

Lastly, the dreaded question, What temps is it good for? This is a very hard question to answer because it all depends on numerous personal factors. Whether someone's body heat typically runs hot or cold, what other layers you have on, how windproof is the fabric, will all affect what temps you’re comfortable wearing it in. When it comes to the warmth of the garment, the fill power and ounces of fill are the best indicators of how “warm” a garment will be. Around 5 ounces of down with a fill power in the area of 850 makes for a warm jacket.

Conclusion

I am hoping that you have read this far and that the info above helped you in some way. If you are looking for a recommendation, I have been ecstatic about is the Grumman by Stone Glacier. It uses 5.3 oz of 850+ fill power DWR treated down with a 90:10 down to feather ratio all stuffed into a soft and comfortable Pertex face fabric. The total weight of the Jacket is 11.8 oz.

With all the options these days available to hunters, it can be overwhelming to decide which one will work best. If you aren’t concerned with your camo matching, or what brand you are wearing, then there are a lot of quality jackets on the market. If you pay attention to the specs we discussed above, then you can’t go wrong.