NOTICE: Certain links on this post may earn a commission for Western Hunter Magazine from Amazon or our other affiliate partners when you make a purchase. Thank you for your support.

Arrow Fletching and its Effects on Flight

Arrow fletching is one of the most common subjects of all the equipment questions I get asked. “Which vane should I use? How many vanes? How much helical?”

Admittedly, there are many combinations for arrow fletching sizes and shapes, and all the variables involved with how to go about applying them. How many vanes? Straight, offset, or helical? How far from the back of the arrow? Wrap or no wrap?

My general thought is that a lot of bowhunters and target archers greatly overthink the arrow fletching subject, hoping for some magic fletching combination that will vastly improve their fletching accuracy. Well, here’s the big fletching secret – you need just the right amount of drag to stabilize the arrow. Not too much, not too little for optimum performance.

It doesn’t much matter how you get it. You could use seven two-inch vanes fletched straight or two five-inch vanes fletched helically. As long as the two fletch jobs produce the same amount of drag, they’ll shoot pretty much identically. Yes, vane weight has some effect, but one set of vanes would have to be significantly heavier than another for that to be a valid concern. The finished arrows with various vane and vinyl wraps used in my testing weighed within 6 grains of each other and still shot together at 50 yards.

Some of you who are paying close attention may doubt what I wrote in the previous paragraph, but it’s true. Even wind drift is a function of drag, and not a singular function of the side profile (area) of the vane itself. This is also why I say you need just the right amount of drag. Too much drag will cause unnecessary wind drift and slows the arrow at long range. Too much drag is less of a problem than too little drag. Too little drag is detrimental to precision (groups). Too much drag won’t hurt precision but may make it tougher to hit what you’re aiming at in windy conditions (accuracy).

Side profile of the vane is part of the equation, but the combined drag of the fletching, arrow, and broadhead drive wind drift.

Confused? For the record, precision describes how consistently arrows can be shot into groups. Accuracy is more about lining up the sight properly to hit what you’re aiming at. I’m guilty of using the two terms interchangeably to avoid sounding like a broken record, but when we’re splitting hairs, that’s the difference.

The Test

For this test, I only considered precision. I didn’t care if the group was off to the side or high or low of the bullseye, because the sight can be adjusted to compensate for that. I only measured group sizes for each three shots with a given vane type.

Different broadhead shapes create more/less drag on the front of the arrow. When the drag in the front becomes too close to the fletching drag on the back, the arrow becomes unstable and won’t group. Since field points create very little aerodynamic drag on the front, almost any arrow fletching can stabilize a target arrow. An exceptionally well-tuned bow can actually shoot bare shafts (no fletching) consistently. However, if you put a broadhead on the front of a bare shaft, you’d be lucky to hit the broad side of a barn, let alone a target! It’s actually dangerous and shouldn’t be attempted.

Getting back to the “big fletching secret” – in order to know how much drag (arrow fletching) you need, you have to consider broadhead size. It stands to reason that a big broadhead will require a similarly large vane. Rather than blindly accepting that as fact, I wanted to gather real test data to prove the correlation and better understand how arrow fletching size and broadhead size correlate.

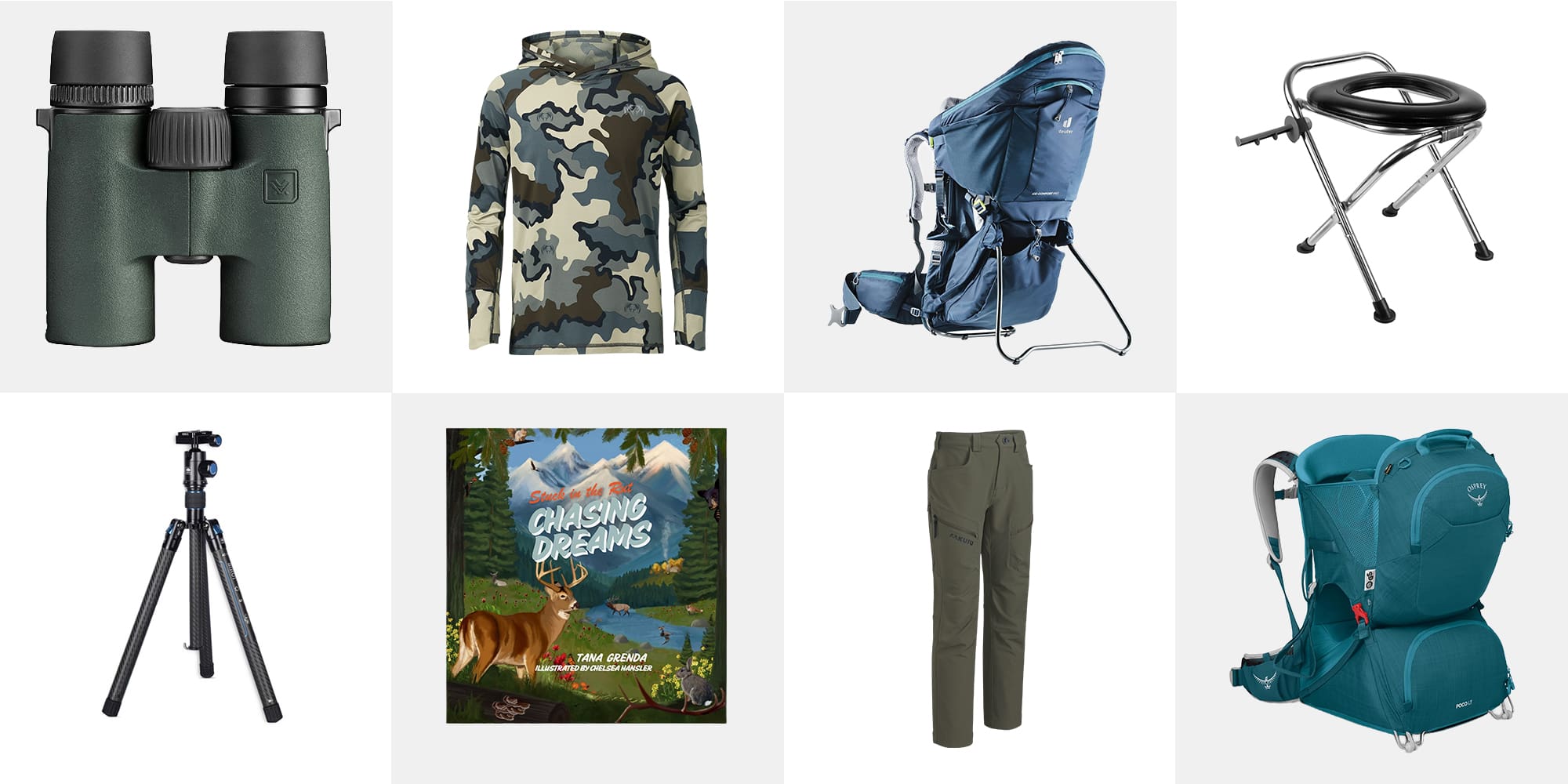

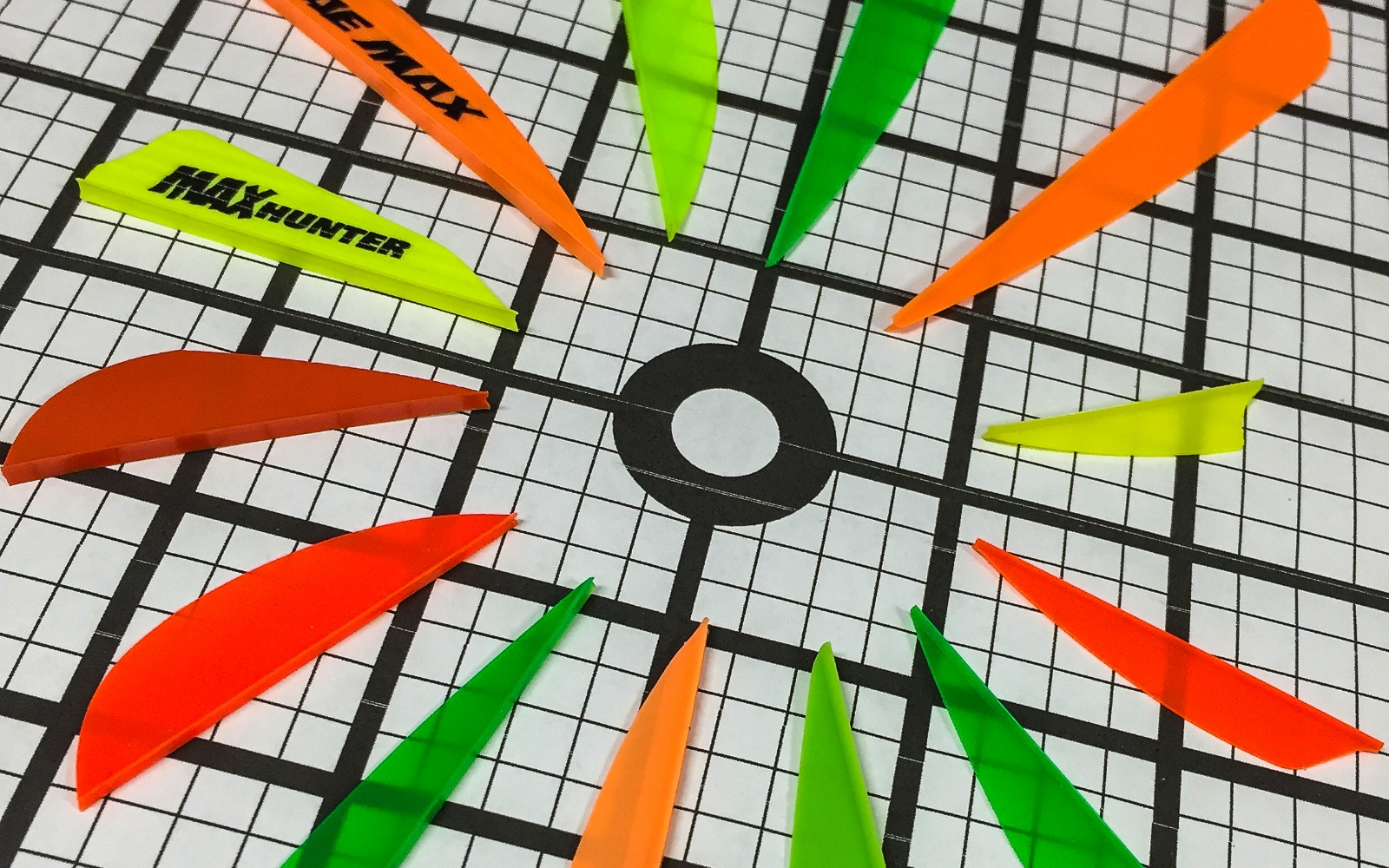

I decided to test three different sizes of vanes (small, medium, and large) with three different broadhead designs (mechanical, small fixed, and large fixed-blade) to see if I could draw some conclusions about which vane sizes worked best with each broadhead.

Large: I used my all-time favorite, go-to vane for fixed-blade broadheads – the venerable Flex Fletch 360. It’s a medium profile, 3.6-inch plastic vane I’ve personally launched through enough critters to know they work.

Medium: AAE Max Stealth. The AAE Max Stealth is a parabolic vane that looks a bit like a smaller version of the FF-360. The Stealth measures 2.7” long x .5” tall.

Small: AAE Max Hunter vane. Similar in profile to the popular Blazer vanes at 2.1” long and .59” high, it came highly recommended by a good friend who shoots mechanical broadheads with exceptional accuracy. Both the AAE Stealth and Max Hunter Vanes feature small steps in the surface along their length.

Clamp: I fletched all three vane types with a Bitzenberger helical clamp to keep the variables to a minimum. I’d have liked to have fletched the small vane with a slight offset or even a straight clamp to mimic how most arrow manufacturers are fletching the shafts you’ll find at the archery shop, but based on my experience, I felt that it was more important to use a helical clamp to increase drag and better stabilize the fixed-blade broadheads.

From this view, you can clearly see the helical twist applied to all three vane types. This view gives us some visual clues about how much drag a given vane should produce.

Broadheads: I selected three very different 100-grain broadheads that I’ve used.

- Mechanical - Rage Hypodermic;

- Medium fixed-blade - Slick Trick’s “standard” 4-blade;

- Large fixed-blade - NAP Razor Cap (this has since been replaced by NAP’s HellRazor design.

Three proven broadhead designs from Rage, Slick Trick, and NAP were chosen for testing. They are equally lethal, yet aerodynamically quite different in their drag requirements.

Hooter Shooter: In order to minimize variables, I borrowed a Spot-Hogg Hooter Shooter from Dead-On Archery in Boise. This machine will hold a bow and allow the user to shoot arrows almost as precisely as your equipment is capable. The aiming is handled by micro-adjustable drives on both axes.

I used a shoot-thru Hoyt Alpha Elite target bow with a 0.7 diopter Swarovski Scope lens to help with the fine details of aiming.

Using a shooting machine is a tedious process that requires patience, good technique, and plenty of spare nocks to get good results.

Arrows/broadheads: Each of the Easton A/C Injexion arrows was checked for straightness, all nocks were replaced, and each cut end was squared with a G5 ASD tool. Each broadhead was checked to ensure alignment was perfect with an arrow spinner. The alignment was also checked throughout testing.

AAE makes arrow prep easy with their max clean wipes. Wipe a dozen shafts down with a single wet wipe and they’re ready for Max Bond adhesive and vanes to be applied in 30 seconds. Fast-set glues make fletching quicker than solvent-based glues of the past.

Testing

The tests were performed at 50 yards, outdoors, over a couple of evenings. Vane types were shot in round-robin fashion so that results wouldn’t be skewed significantly by varying wind conditions. Most shots were within two minutes each other.

The wind was a factor by design to mimic typical hunting conditions, but I made every effort to avoid “gusts”. Shooting in the crosswind should also give us an idea of how different vanes are affected by the wind with a broadhead attached.

Once the machine was set up, I shot several groups with field points to establish an accuracy baseline. It quickly became apparent the machine was capable of very precise groups with each vane type. I was able to consistently get groups smaller than one inch with the mixed vanes, and some were much tighter. The individual arrows were generally hitting within ½” of their previous impacts. After crushing the back end of several arrows, I was confident in the precision of the setup.

You can tear up hardware pretty quickly shooting at the same spot with a Hooter-Shooter. The back end of the AAE Max-vaned arrow was hit by the Flex Fletch-vaned arrow, which propelled a large carbon splinter carrying an AAE Max vane into the block target.

Machine tuning: Past experience has shown that the machine doesn’t “grip” the bow exactly as I do, so it often causes a significant difference in the tune. A bow tuned in my hand will often tear badly when shot through paper with the machine. A poorly tuned bow usually won’t group well with fixed-blade broadheads. Therefore, I made tuning adjustments to get the fixed-blade broadheads to group with the field points. When the broadheads started to group with field-points, I locked down the rest and got ready to collect data.

In succession: I started with the Rage Hypodermic by shooting alternating shots with each vane type until I had shot each one six times. Next, I shot the Slick Trick in a similar fashion. Finally, I shot six sets with the big nasty NAP Razor Caps the same way.

I logged every shot and calculated group sizes and horizontal spread. During the process, I made a decision to re-shoot a few errant shots that I felt were likely operator error. While the shooting machine is accurate, it can be sensitive to shooter errors like resting a hand incorrectly or not being gentle with the release. Some of the flyers could have been “real”, but I felt like the data would be easier to interpret without a few outliers that would skew more obvious trends.

Observations

Without surprise, the groups got larger with the larger broadheads. The group size increased by 50% for both of the smaller vanes with the large fixed-blade broadhead versus the mechanical broadhead. Interestingly, groups only increased by 37% with the larger vanes.

The change in group size between the Rage and the Slick Trick was less than the step between the Slick Trick and the Razor Cap for all three vanes. This is shown by the slope of the lines getting steeper as they progress from small to large broadheads. The Flex Fletch 360 performed better than the smaller vanes with the large broadhead, but all three seem to produce adequate stability under test conditions.

Even though the Rage is a very accurate mechanical broadhead, it didn’t group nearly as well as the field points I used during setup, and that stands to reason since there are exposed blades that will add drag to the front of the arrow. Rage acknowledges this and sends special practice points so the flight of practice arrows will better mimic broadhead flight.

Don’t assume that your expandable broadhead will shoot just like your field points. As expected, the Rage shot best in this test, but not nearly as tightly as the field-points grouped during setup.

At the left of the plot, you can see that the smaller vanes grouped a little better with the mechanical broadhead than did the larger Flex Fletch 360 vanes. I attribute the 11% difference mostly to horizontal wind drift. Conditions, when the Rage was tested, were somewhat breezy in the early afternoon and the shorter vanes should exhibit less drag-induced wind drift. Calmer conditions likely would’ve produced tighter groups and less difference between the three vanes.

By this same logic, I’d have expected the Max Vane to group better than the Stealth. Perhaps the slightly larger Stealth stabilized the Rage a little better than the Max with little added wind drift. Small difference, but interesting…

A crossover occurred with the Slick Trick broadhead at the middle of the plot where the Flex Fletch vane grouped 5% tighter than the two shorter vanes averaged. Based on the variability of the testing, 5% may or may not be a statistically significant value, but I think there is an undeniable trend showing that as drag on the front increases, additional drag at the rear helps.

You can also infer from the plot that larger vanes are less susceptible to broadhead changes. The small difference in group size between all vanes here indicates that all three vane designs are probably good choices for the 1” cutting diameter Slick Trick.

Finally, the far right shows a larger group size spread with the largest broadhead. The groups jumped 28% between the Slick Trick and Razor Cap. That sounds like a lot, but in fairness, remember the larger cutting diameter of the Razor Cap gets 1/8” of that back. The NAP HellRazor is probably the best suited for elk hunting of the three, and a 2” group at 50 yards is plenty to get the job done.

At the far right, the FF360 vane grouped 13% better than the small vane average. I think the margin would be higher if the smaller vanes were fletched with a 2-degree offset, as many factory-fletched arrows are. If you buy your arrows already fletched, you may not have enough drag to stabilize a larger fixed-blade broadhead like the HellRazor or even the smaller Slick Trick.

Lessons

I’ll offer one final recommendation: Use a little more drag than you need to avoid flyers. I’ve experimented a lot with shorter vanes and fixed-blade broadheads to try and minimize wind drift. I always shot good groups with those setups.

However, I always seem to get an occasional flyer I can’t explain. An arrow that unexpectedly shoots errantly might only happen one out of 100 shots. At that rate, I tended to accept them as a fluke. However, I’ve found that those flyers pop up again on critical hunting shots. Not good…

My theory is that when you have less drag, the arrow doesn’t recover as quickly if the shooter makes a mistake. If the arrow gets launched a little funny from being nervous or shooting from an awkward position, an arrow with more arrow fletching drag should better stabilize a less-than-perfect shot. It’s likely more of a factor when using larger fixed-blade broadheads, so you won’t likely get any of these flyers with field points.

Aside from tuning, wind drift and stability are the two most influential factors affecting broadhead flight. Matching the appropriate vane with your broadhead can improve your precision and accuracy if you can get just the right amount of drag to stabilize the broadhead.

I think almost any vane type can work with almost any broadhead. If you have a particular vane shape that you like, you can experiment by adding a fourth vane or by adjusting the helical or offset until you feel you’re getting enough drag to produce the best groups possible with your broadheads. If you see an occasional flyer, it might be a sign you need a little more arrow fletching.

It’s a Wrap

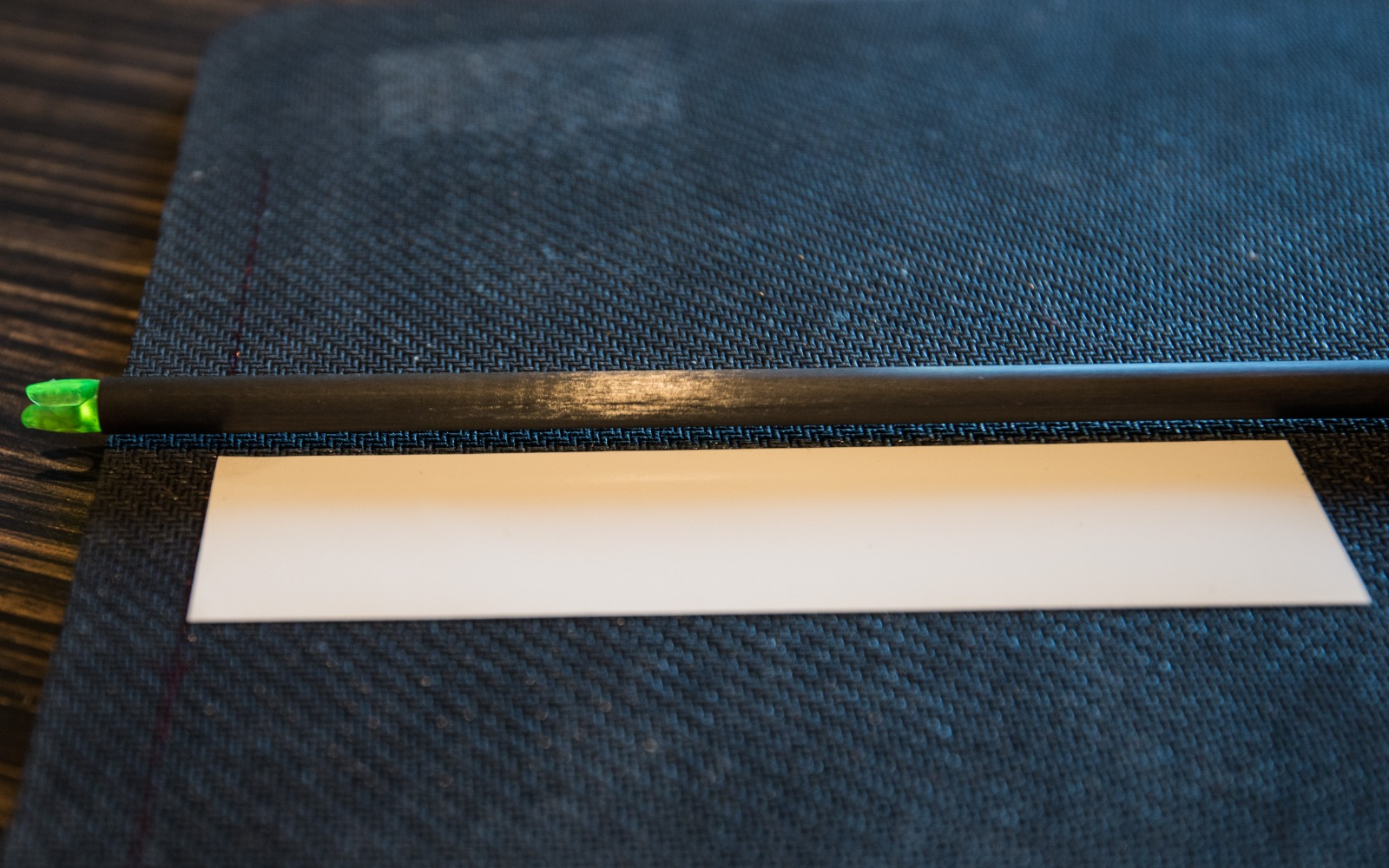

I like using wraps because my arrows stand out and they provide a good foundation for fletch adhesion. I flip my mouse pad over and make a mark to help line up each wrap consistently.

I start each wrap by rolling the arrow about ¼ turn. Then I finish by turning the shaft while rubbing the wrap onto the arrow. This helps keep bubbles out from under the vinyl film.

Less is more when it comes to fast-set glues. I apply a bead and then use my finger to wipe away excess, leaving a thin film on each vane. Wipe the excess from your finger onto a disposable towel and apply the vane.

The result is a clean-looking, durable arrow fletching job that will make your arrow easier to find after they pass through your trophy.