NOTICE: Certain links on this post may earn a commission for Western Hunter Magazine from Amazon or our other affiliate partners when you make a purchase. Thank you for your support.

The Arrow Ballistics Study Results

Results from the Arrow Ballistics Study have been way more anxiously anticipated than I ever imagined. I have received thousands of comments, direct messages, text messages, and emails about this study. It's obvious that the same questions and curiosity that sparked my interest in this study in the first place are burning inside others as well. Questions like, is there a sweet spot in terms of vane shape/size/quantity that optimizes arrow flight for field tips, mechanicals, and fixed blade broadheads; which broadheads are most aerodynamic; which broadheads fly the best (most accurate/group the smallest); what vane shapes “control” broadheads best; how much advantage is there to 4-fletch versus 3-fletch; what vane shapes are the quietest; is there an advantage to shooting 4mm arrow shafts?

Quick Jump Menu

Study Origins

Assembling the Perfect Team

A few Definitions

Purpose Statement

How the Study was Conducted

A Little More Preamble

The Results

Which were the most accurate broadheads?

Which were the most aerodynamic broadheads?

Which were the most aerodynamic fletching configurations?

Which fletching configurations controlled broadheads best?

Which fletching configurations had the best combination of drag and lift recovery for you?

Did 4mm arrows have an advantage over larger diameter shafts?

How much impact did arrow length have on arrow drag?

One final plot to blow your minds!

Conclusion

Study Origins

These questions become even more critical because of confusing or misleading advertising from manufacturers; these manufacturers (or influencers they’ve paid) all claim their stuff is the best. What exacerbates this problem is that there doesn’t exist a governing body to unify any sort of standards for ballistics in our industry, so manufacturers can essentially claim whatever they want, and it’s not consistent among manufacturers.

To make it worse, there is hardly any independent/third-party testing to prove or disprove manufacturer claims in our industry. Lots of bowhunters, including myself, have taken matters into their own hands and have conducted small experiments to put some of these questions to the test, but without the proper tools, it can be almost impossible to come up with definitive answers, especially results that are controlled and factual enough to publish.

A few years ago, I conducted an independent arrow audit among the major arrow brands in the industry and wrote about it in Western Hunter Magazine. I looked at shaft straightness, weight, and spine consistency. With spine, I not only looked at shaft-to-shaft consistency but also looked at the consistency of spine around a single shaft at different rotations around the shaft. I was pretty shocked at the results I came up with compared to what some manufacturers claim.

Once I successfully completed the independent arrow audit project, my attention turned to vanes, broadheads, and arrow builds in general. If I were going to independently test these things, I would need some help. I have been in the industry long enough and have strong enough connections that I started thinking about the team I could assemble to help me conduct a huge independent Arrow Ballistics Study. I say independent emphatically. A strong emphasis of this study was to conduct it WITHOUT ANY manufacturer influence or bias.

Assembling the Perfect Team

The first person that came to mind was Tristan from Precision Cut Archery (PCA). Tristan and I are cut from the same cloth, both really technical and analytically-minded, and I knew this would be right up his alley. The power of his Precision Cut Archery ballistics engine was exactly what we needed to evaluate and test each arrow build ballistically.

The next component was ensuring we had a perfectly controlled shot, which required eliminating the human element from the shot. For this, I approached Easton because I knew they had a pneumatic, precision shooting machine that is capable of shooting extremely consistently. Beyond that, a huge thank you to Easton, who selflessly funded the project and loaned us multiple engineers and media people.

Sound analytics were conducted by Jaime at Archery Sound Lab, using a purpose-built sound chamber. He has a degree in acoustics and is a very passionate archer.

Lastly, we needed help building over 300 different arrows, and for that, we looked to Jace Johnson and Black Ovis’ Arrow ID. They did an outstanding job building the arrows to a very high standard.

A few Definitions

An arrow’s trajectory is dominated by three main factors: arrow launch velocity, arrow weight, and aerodynamic drag. Drag is a force that opposes the arrow’s forward motion because of air resistance and causes the arrow to slow down, which alters its trajectory.

Fundamentally, an arrow follows a parabolic trajectory based on the launch velocity, arrow weight, and gravity. Once the arrow is launched, however, another force starts to act on the arrow, which is due to air resistance. With air resistance, arrow drag comes into play and has a major effect on the parabolic trajectory curve, as well. Since arrow weight and arrow drag both affect the arrow’s trajectory simultaneously, it can be a bit complicated trying to determine how each one affects the trajectory individually, but with PCA, we can isolate the drag component by calculating a drag coefficient.

To put it in relevant hunting terms, think of a drag coefficient for arrows like a ballistics coefficient for bullets (it’s not quite the same thing, but close enough for this discussion). These drag coefficients can be used to compare the ballistic efficiency of different arrow designs.

It should come as no surprise that any fletching on the back of the arrow increases drag, but vanes on the back of the arrow are critical to stabilize the arrow. There is another force at play here called lift. Lift is a force perpendicular to the airflow and is the force that stabilizes the arrow. It is generated based on the shape of the vanes, which creates a difference in pressure on the two opposing sides of the vane.

This difference in pressure causes the stabilizing effects, similar to how an airplane wing generates higher pressure below the wing and low pressure above the wing, resulting in lift, or how air flow across a wind turbine blade causes the blade to turn.

Drag and lift are not the same thing in fluid dynamics. A vane produces both drag and lift, though. Think of lift as the corrective force trying to stabilize the arrow; it’s a good thing to help the arrow fly true. Drag is like an undesirable byproduct of the vane that opposes the arrow’s motion and slows it down. Unfortunately, lift and drag kind of go hand in hand. In an ideal world, the perfect fletching configuration would maximize lift and minimize drag. A BIG reason for this study is to determine vane shapes and fletching configurations that minimize drag while maximizing lift.

It does you no good to maximize the ballistic efficiency of the arrow if the vanes don’t produce enough lift to quickly stabilize it. So, there is a balance that needs to be met, and that balance is different depending on the intended purpose of the arrow.

Purpose Statement

The purpose of the ballistics study is to gain a science-based understanding of the fundamental governing aspects of arrow external ballistics. In particular, to study how an arrow’s components (vane configuration, arrow length, arrow diameter, point/broadhead) affect ballistic properties such as aerodynamic drag and corrective lift (how an out-of-tune arrow corrects itself), and therefore, how an arrow build can be optimized for specific purposes, such as hunting different species and various target archery events.

Specifically, this study will provide insights to optimize arrows for their intended purpose by providing data to make sight tapes (arrow trajectory modeling) more accurate and easier to calculate; calculating an arrow drag coefficient for different arrow diameters and lengths; providing a science-based means to make fletching configuration recommendations for various purposes (field tip, mechanical broadhead, fixed blade broadhead). For example, this study will provide the data to recommend a minimum vane configuration to steer a fixed blade broadhead, or for mechanicals, the study can recommend a different vane configuration to minimize drag and maximize trajectory.

How the Study was Conducted

The following is a brief description of how the testing was conducted. For a more in-depth look, please refer to my article Archery Ballistics Part 3 in the July issue of Western Hunter Magazine.

Each distinct arrow design tested during the study had 6 arrows built in that configuration (two shooting rounds of 6 arrows each). The following arrow build components were tested:

- 3 different arrow diameters

- 3 different arrow lengths

- 34 different vane configurations (various vane models and different configurations)

- 27 different point tips (field tips, various mechanical and fixed blade broadheads)

During the testing, we had a baseline arrow design, which consisted of the following control components:

- Arrow Diameter: 5mm Easton Axis

- Arrow Length: 27” (carbon to carbon)

- Vane Configuration: Three AAE Max Stealth, Bitzenburger Right Helical, 2° offset

- Field Tip: Gold Tip Ez-Pull Field Tip

- Mechanical Broadhead: Sevr 2.0

- Fixed Blade Broadhead: Iron Will Wide

All arrows were shot out of a 2025 Hoyt Alpha AX2 29 with a Hamskea Epsilon rest. The bow was set up at a draw length of 28 inches and a draw weight of 70 pounds. The launch velocity of the arrows varied because of the different arrow weights, but the baseline arrow build produced a launch velocity of 287 FPS. Velocity readings of all arrows shot were captured at launch and 60 yards down range with Garmin Xero C1 Pro chronographs. Precision Cut Archery Software was used to calculate distinct drag coefficients for each unique arrow build.

To estimate the effects of lift recovery, the bow was intentionally brought out of tune horizontally (manipulating the rest and cam lean) as well as torqued horizontally in the shooting machine (torqued the same way for every shot). The result of the tune and the torque was a paper tear of 1.5” at 15 feet. All fletching configurations were shot at 70 yards with a field tip, mechanical, and fixed blade broadhead, a total of 4 shots each. It would have been impossible to test every single broadhead with every single vane, so the testing team chose the Sevr 2.0 to represent mechanicals and an Iron Will Wide to represent fixed blades.

Since the bow was out of tune and torqued, the arrows were launched with a horizontal misalignment, which forced the vanes to attempt to correct the arrow’s flight. Obviously, the broadhead arrows drifted more than the field tip arrows. The degree to which the vanes corrected (or did not correct) the arrow’s flight was quantified by measuring each arrow’s impact location compared to a fixed point.

The impacts of all arrows were recorded with photos, and then those photos were analyzed with Blue Beam software to measure the distance from the fixed point to the arrow impact. Comparatively, the greater the lift force of a particular fletching design, the lesser the measured displacement between the fixed point and the arrow’s impact. This is a practical way of measuring the effects of the lift force for bowhunters. This test was not intended to quantify the lift force itself, but the effect the lift force of the vane has on its ability to correct the flight of the arrow.

A Little More Preamble

Before I deep dive into the results of this thing, there are a few things I need to mention first. This test is in no way, shape, or form intended to bash, call out, or discredit any one brand nor manufacturer. We have conducted this study to the best of our ability, budget, and time constraints. I’ll be the first to admit that I wish we had more time to shoot more arrows of each design to get bigger sample sizes, but we did the best that we could.

There is no governing body that dictates how arrow ballistics are to be tested, so we have done things according to how we thought best. Also, we are doing this for no gain of our own. None of us has skin in the game, and no one on this team has been paid or incentivized to skew results one way or another; I’ve made damn sure of that. In fact, we bought all of the products that we tested in this study (they weren’t even donated to us). We are essentially doing this to fulfill our own curiosity and providing results for free to the public “out of the kindness of our hearts” and for the betterment of archery.

I have seen some scientific testing directly from some manufacturers, and I respect any sort of scientific approach to designing products and supporting claims. I hope this study inspires more of that in this industry, making manufacturers think twice or do some testing before making claims. I also hope that it inspires more third-party testing.

The Results

Here in Western Hunter, I am going to go over the results of this study, based on my interpretation for the western hunter. I am going to present these results in a question-and-answer format. I’ll state a question and then answer it with a description and data from the test. And without further ado, the results:

Which were the most accurate broadheads?

Quantifying broadhead accuracy was not a primary focus of the study; however, the team saw strong trends and wanted to mention the results that were captured. The team noted group sizes and captured photos of the broadheads that produced the best groups.

During the ballistics testing, each broadhead was shot in groups of 6 arrows for 2 rounds with the baseline arrow build. The mechanical broadheads that grouped the tightest out of the tuned bow (in no particular order) were the Schwacker 261, Sevr 1.5, Sevr 2.0, and Thorn Rift 2.2. The shooting machine consistently shot field tips in 2-3” groups at 70 yards. For these 4 broadheads, the shooting machine was consistently shooting the same size groups as the field tips.

Each one of these broadheads broke arrows and cut vanes while shooting these groups. The Beast broadhead and the Sevr 1.5 Hybrid both performed really well, also. Both shot groups in the 3-3.5” size. All the other mechanicals shot groups ranging from 4-5”.

The tightest-shooting fixed blade was the Evolution Jekyll. Both groups with the Jekyll were slightly over 3”, which was really impressive. The two next best flying fixed blades were the Slick Trick Standards and the Grim Reaper Micro Hades. Both of these shot groups about 5.5-6”. Most of the other fixed blade groups were about 6.5” or bigger.

In general, we saw the average field tip group was 2.5”, the average mechanical group was 4”, and the average fixed blade group was probably 7”. It should be noted that the same baseline arrow shafts were rotated through all of the broadheads in this testing (to try and reduce any arrow bias). This just goes to show how much more forgiving a mechanical broadhead is than a fixed blade broadhead, considering the increase in group size when shooting even from a controlled shooting machine.

Which were the most aerodynamic broadheads?

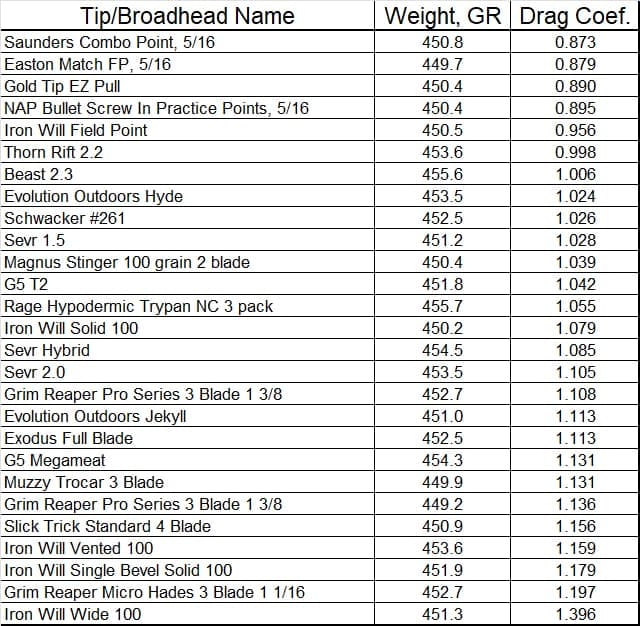

One of the major focuses of the study was to quantify drag coefficients for arrows tipped with different broadheads. To do this, we used the baseline arrow build and shot every broadhead 12 times using Garmin Xero C1 Pro chronographs to capture launch and 60-yard velocities. We used PCA to calculate drag coefficients from these velocities. The following drag coefficients were calculated (smaller number means less drag, more aerodynamic).

Broadhead length and the tip type/shape seem to have the biggest impact on aerodynamic drag. Chisel-tip-type tips seem to have more drag, and really long broadheads also clearly have more drag. This doesn’t necessarily mean that they fly less accurately, though. For instance, the Sevr 2.0 was one of the best grouping mechanicals, but has more drag than other mechanicals because it is longer. As you’d expect, the Thorn Rift and Beast broadheads were the most aerodynamic and pretty much tied for first place in this category.

The Schwacker 261, Evolution Hyde (a little surprising), and Sevr 1.5 all pretty much tied for second. Perhaps the most surprising entries from the ballistics testing were the Iron Will Solid 100 and the Magnus Stinger 100. Both of these fixed-blade broadheads had less drag than many of the mechanical broadheads.

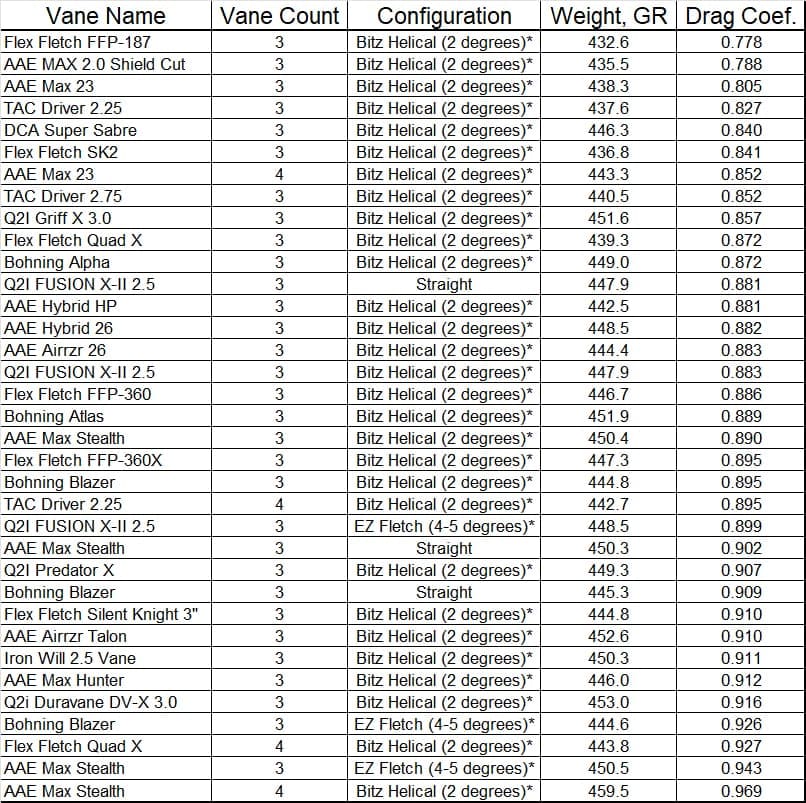

Which were the most aerodynamic fletching configurations?

This question is a little difficult to answer from a hunting perspective. Obviously, no vanes on the back of an arrow would produce the most aerodynamic arrow build, but this isn’t practical. You need enough vane on the back of your arrow to quickly stabilize it; otherwise, it won’t be accurate. Nevertheless, here is the table showing the drag coefficients calculated from shooting all of the fletching configurations with the control arrow build:

Which fletching configurations controlled broadheads best?

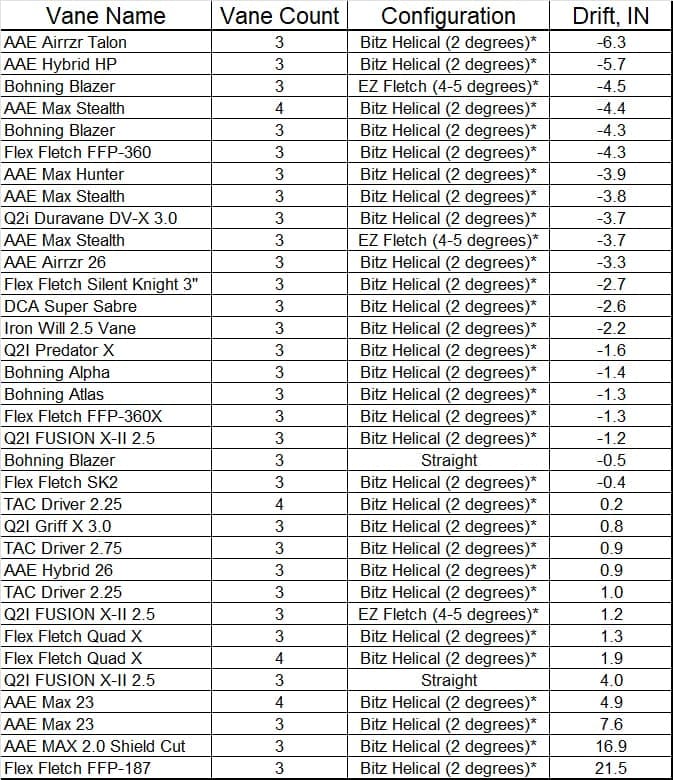

This was one of the primary questions we set out to understand in this study with our controlled shooting machine. This is kind of a loaded question that I will answer several different ways throughout this article. The vane that performed the best during the lift recovery testing, meaning it had the least amount of horizontal drift when shooting the control fixed-blade broadhead (bow was out of tune shooting the Iron Will Wide), was the AAE Airazr Talon 3.0.

Here is a summary showing the amount of drift each fletching configuration produced shooting the Iron Will Wide. Note that this table shows the amount of drift for each fletching configuration compared to the arithmetic average drift from this test. So, with the AAE Talon, it drifted 6.4” LESS than the average from this test (the negative implies less than the average). The Flex Fletch FFP-187 drifted 21.4” MORE than the arithmetic average drift.

Which fletching configurations had the best combination of drag and lift recovery for you?

This is undoubtedly the single most important and frequently asked question about this study. Unfortunately, it’s not the most straightforward to answer. Having enough vane on the back of your arrow is essential for stabilizing the arrow quickly, but too much vane can slow your arrow down significantly, especially at long range. For a western hunter, maximizing the flatness of your trajectory is a very important aspect of setting up your bow and arrow.

If you’ve spent any time following me or my articles, you know I preach the importance of range forgiveness for western hunting. The most common mistakes in western hunting revolve around miss-ranging (even with a range finder), so designing your arrow to mitigate this is so important. Having a flat-shooting arrow promotes good range forgiveness. So, there is a balance that needs to be met when designing your arrow between lift recovery and drag. That balance is highly dependent on what broadhead you are shooting, how tuned your bow is, and how well you, individually, are able to shoot in the heat of the moment with potentially awkward angles or bad footing.

You have to be very real with yourself and your shooting ability to answer this question. You essentially want to shoot as little vane as you can get away with, knowing your own shooting abilities. For example, you can get away with significantly less fletching when shooting a low-profile, good-grouping mechanical broadhead, but for fixed blade broadheads, even for very experienced shooters, having enough vane is important to counteract any planing of the broadhead. Even if you are shooting a mechanical broadhead, but you know you tend to rush or pull a shot in the heat of the moment, you need to design your arrow with more lift recovery (vane).

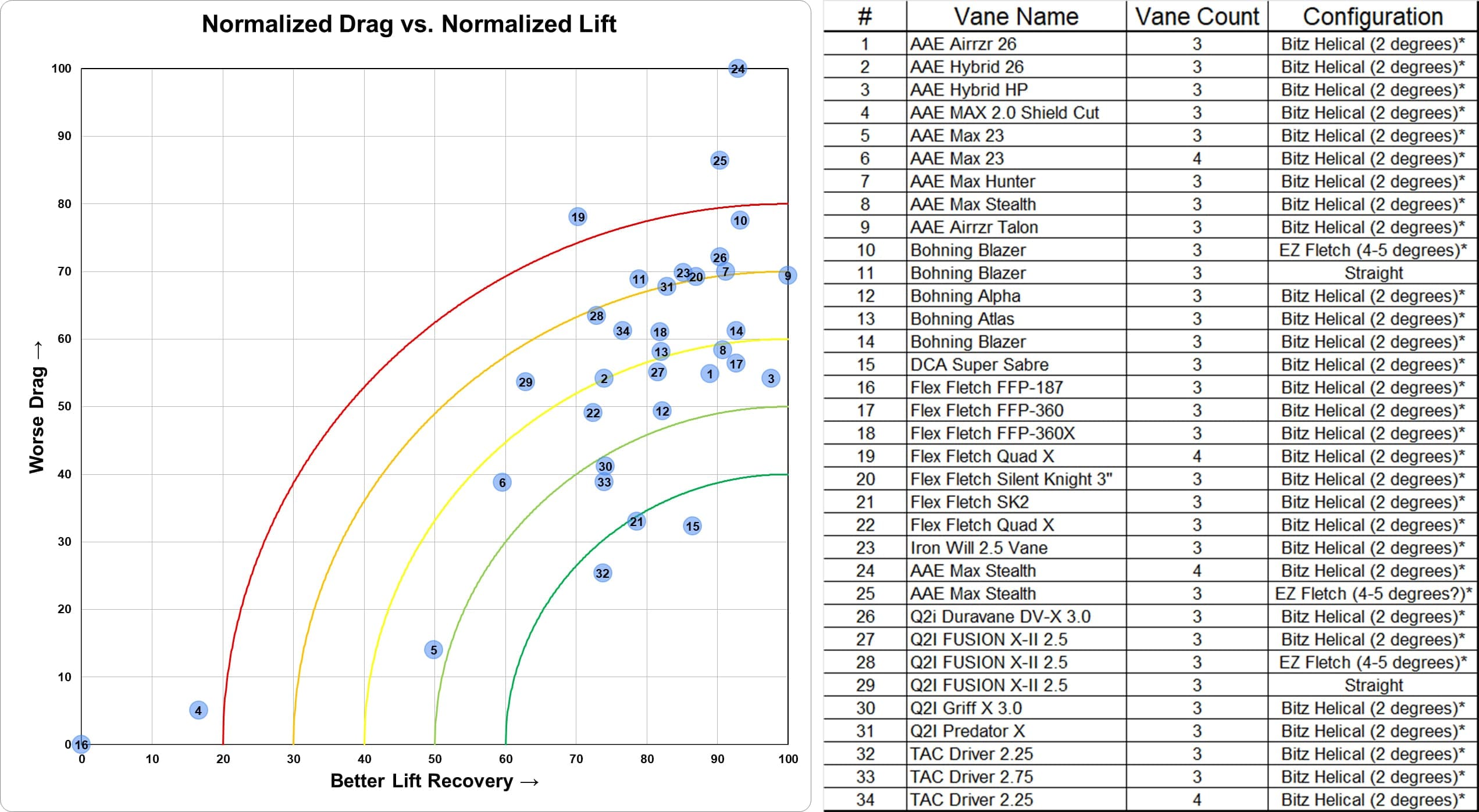

The following is a Lift versus Drag scatter plot of all the fletching configurations shot during the study. This plot doesn’t actually show the magnitude of the force of lift; it shows the effects of lift by quantifying the displacement of broadhead impact location. This is a comparative plot where all of the values for both lift recovery and drag have been scaled (normalized) relative to one another, such that the worst-performing fletching configuration for drag measured during the study is 100% and the best-performing is 0%.

The opposite is true for lift recovery; the best-performing fletching configuration for lift recovery is 100% and the worst is 0%. So, if a vane configuration scores 100% for lift and 0% for drag, it’d theoretically be the best vane configuration in the test. Again, the values of 100% and 0% don’t actually mean the vane has perfect lift and no drag (that’d be impossible); it just means it’d be the theoretical best performance recorded in this test.

The lower right-hand corner of the plot represents this theoretical best value of 100% lift and 0% drag. That means that the closer a vane configuration is to this point, the better its combination of lift and drag. The green, yellow, orange, and red arcs are plotted to help the reader visually see relative radial distance from this ideal point. These arcs also create performance bands to help rank a vehicle configuration’s performance. The 3 vane configurations 15, 20, and 31 (DCA Super Saber, TAC Driver 2.25, and Flex Fletch Silent Knight 2”) inside the dark green arc, for example, are excellent performing vanes (meaning they have a great combination of high lift recovery and low drag).

Just because these 3 vanes are the highest-performing vanes in the study, doesn’t necessarily mean they are the perfect vanes for you. For example, I wouldn’t recommend shooting any of these vanes with a big fixed-blade broadhead. They simply do not generate enough lift recovery to control a potential poor shot with a fixed blade during an exciting hunting encounter. However, some bowhunters will do fine shooting a streamlined mechanical with any of these vanes.

If you do tend to shank a shot (being honest with yourself), these may not have enough lift recovery even for a mechanical. For example, I’ve got a friend who repeatedly shanks shots on game, and even though he shoots mechanicals, I fletched him up some arrows with AAE Talons to help mitigate the drift from his shanked shots. The other thing to consider is that this plot doesn’t show vane noise. I am a huge believer in a quiet vane, so noise is a big part of my personal vane selection.

The other groups of vanes that look like good all-around performers to me are 29 and 32 (Q2i Griff X 30 and TAC Driver 2.75). The conglomeration of vanes 1, 3, 8, 9, 14, and 17 (AAE Airazr 26, AAE Hybrid HP, AAE Max Stealth, AAE Talon, Bohning Blazer, and Flex Fletch 360) all show an excellent amount of lift recovery without having excessive drag and look like great vane choices with more emphasis on lift recovery.

Which vane configurations were the quietest?

As I said above, arrow noise is a critical factor for me. To me, it’s way more critical than the sound of the bow going off. The sound of a bow going off is an extremely short, non-continuous sound that sounds similar to a stick breaking in the woods. There is no doubt animals hear it, but it's not as threatening as the hissing sound of an arrow coming straight at them. An arrow’s “hiss” is completely unnatural sounding and is a continuous noise that they can literally hear getting closer to them. Their instinct is to react to any threat that is getting closer to them.

I think it’s the arrow that causes the deer’s duck-and-flight reaction, not the bow (assuming you aren’t shooting sub-20 yards). I have no doubt the sound of the bow going off puts them on alert, which certainly doesn’t help, but the combination of the bow going off, putting them on alert, and then hearing the hiss of a loud arrow heading straight toward them is a bad combination.

Both the fletching configuration and the broadhead contribute significantly to the noise of the arrow. We did not have enough time or budget to test the broadheads in this study for noise. Simply put, for broadheads, avoiding vented blades or lots of exposed blade surface area will greatly reduce the noise of your broadhead. Mechanicals are generally quieter than fixed blades, and the really streamlined ones are very quiet. Fixed blades that are really quiet have smaller diameters and solid blades.

We did conduct an in-depth vane noise study as part of the Arrow Ballistics Study. We partnered with a company called Archery Sound Lab to do this because of the cost and time associated with doing it ourselves. Jaime at Archery Sound Lab has a master’s degree in Acoustics and is a passionate archer. He has a purpose-built sound chamber for testing arrows with all of the appropriate equipment and knowledge to do it correctly.

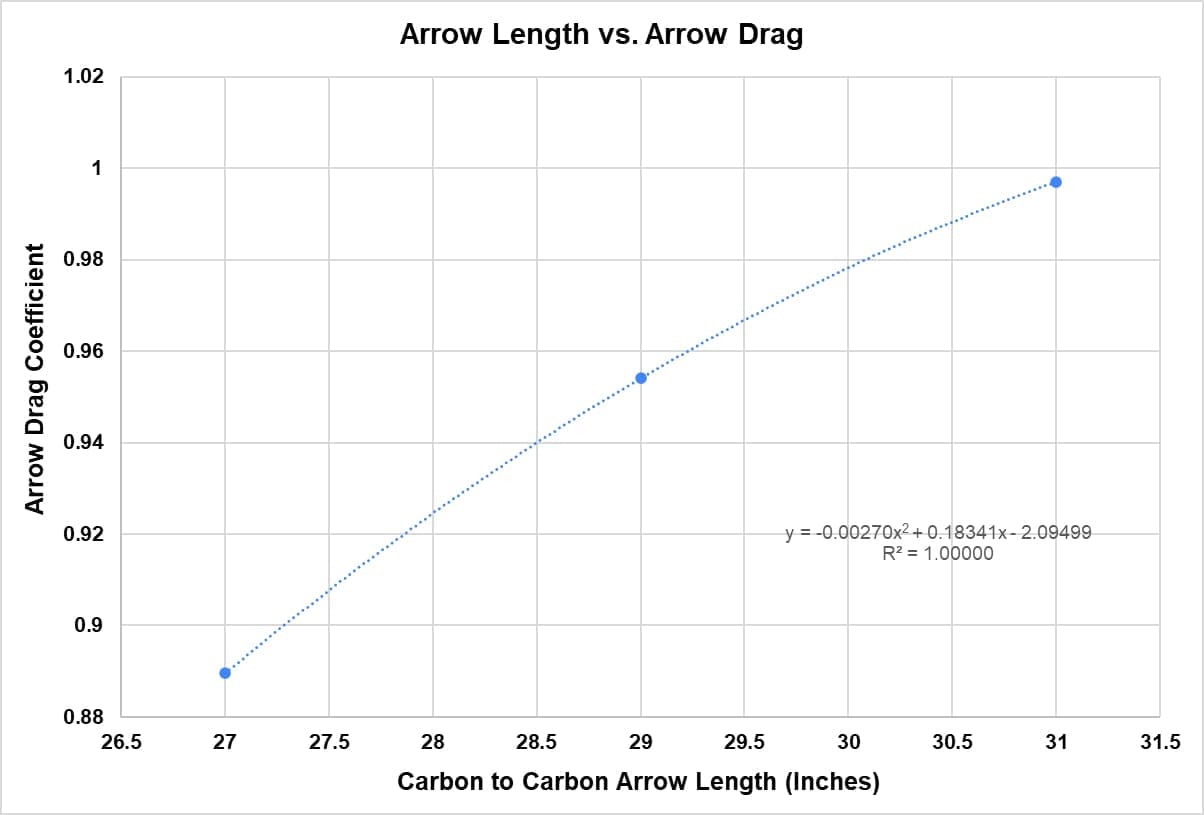

A big part of this study was to isolate the vane noise from all external noises (this is easier said than done). One of his biggest contributions was being able to synthesize the data and report it based on how a deer hears it (one octave higher than humans). A more detailed description of the sound testing will be forthcoming. Here is a table with the results of the sound testing we did. I’m not surprised, but the Flex Fletch 360 takes the cake. I have shot this vane for 10 years, largely because it’s the quietest vane I’ve ever found.

What makes this vane even more impressive is how quiet it is for how good it corrects broadhead flight (one of the top-performing vanes from the lift recovery testing). Keep in mind when analyzing this table that a difference of 10 decibels actually translates to twice as loud. It sounds weird, but that is actually how the decibel scale works. So, the Flex Fletch Quad X 4-fletch is twice as loud as the Flex Fletch 360 3-fletch.

Did 4mm arrows have an advantage over larger diameter shafts?

Yes, they did! During the testing, we used our baseline arrow build to iterate on arrow diameter. We tested 4mm shafts, 5mm, and 6.5mm. According to the ballistics testing, 4mm arrows had a drag coefficient that was 10% less than 5mm arrows. This may not sound significant, but bowhunting is a game of inches, and that decrease in drag can lead to multiple inches less drop and less wind drift at extended range. A couple of inches is the difference between a wound and a solid kill simply by choosing a slimmer shaft.

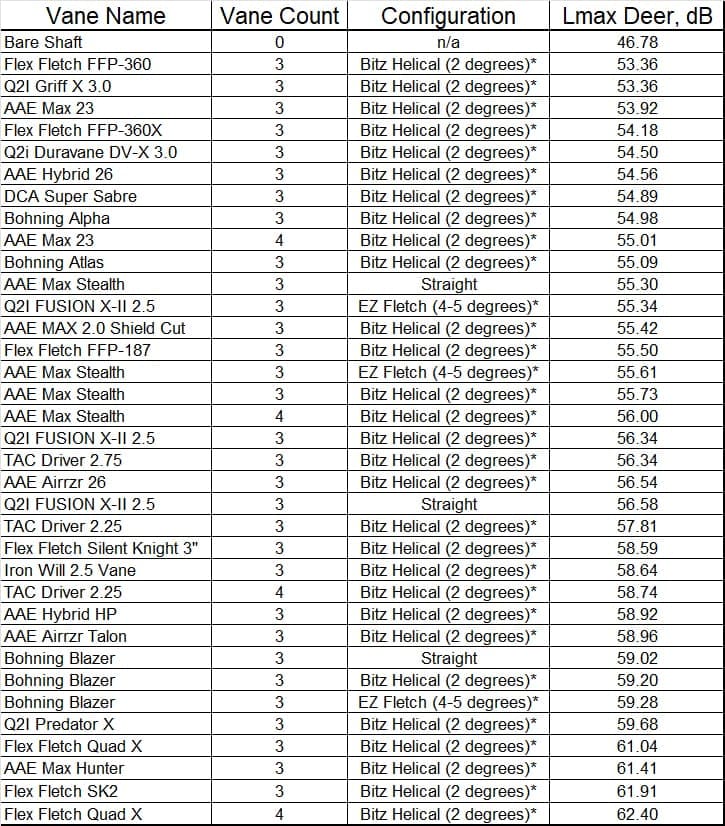

How much impact did arrow length have on arrow drag?

During the study, we used the baseline arrow build and iterated on arrow length to determine a correlation between arrow length and arrow drag. We tested carbon-to-carbon arrow lengths of 27”, 29”, and 31”. Note that the 27” arrows were 300 spine, and the 29” and 31” arrows were 260 spine, so there was a slight diameter change between spines. Nevertheless, the ballistic data from the study shows a strong correlation between arrow length and arrow drag.

The following plot shows that arrow drag appears to be proportional to arrow length squared. Comparatively, there is a 12% increase in drag coefficient going from 27” to 31”. That is more than I would have suspected. Based on this data, there is a strong basis for cutting your arrow as short as you can. Obviously, cutting your arrow shorter affects tune, and a good tune trumps a decrease in drag, but if you can shorten your arrow and keep it tuned to your bow, you will decrease drag and crosswind arrow drift.

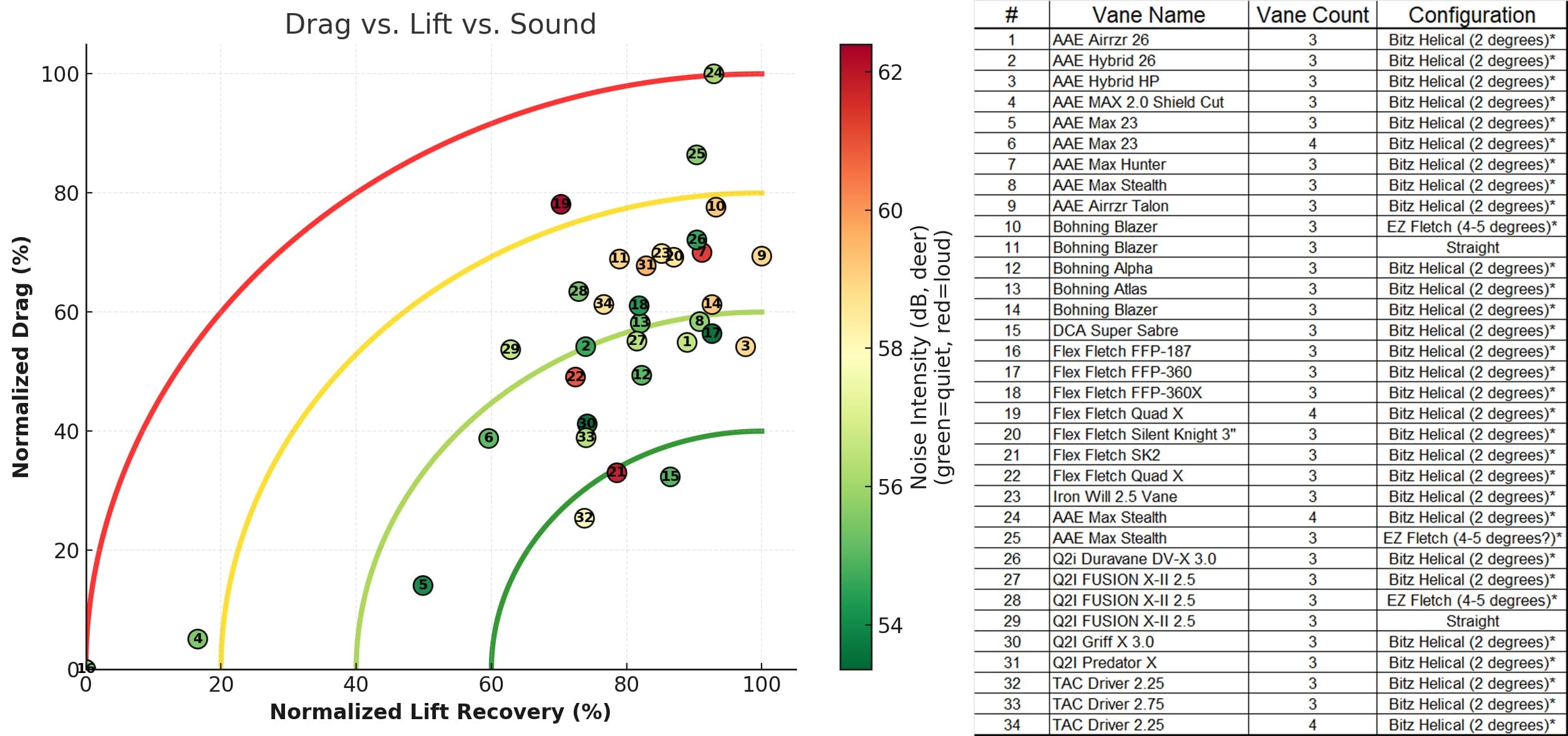

One final plot to blow your minds!

This plot shows the same drag-versus-lift that was presented above, but each dot has been colored to show the respective noise intensity of that vane configuration. So, it shows drag versus lift versus noise intensity. The green color means quieter, and the red color means louder. If I had to boil this study down to a single plot, it would be this one. Take all the time you need to ponder this one!

Conclusion

The Arrow Ballistics Study was very successful. We captured a ton of very meaningful data that have answered a lot of my own questions, and I know will answer a lot of questions for many of you. The study has also opened the door to new questions and new vanes that I am curious to test. Next year, we are planning to conduct another study (in fact, we’ve got a lot of support to make this an annual event), where we want to drill down a little deeper on some of the topics tested in this study, as well as study new topics like FOC and wind drift.

There are a lot more questions that could be discussed about this study than I have included here, but I needed to start and stop somewhere and get some results out on the street before I started getting death threats – HA! This article just touches the surface as far as results go, giving you a lot of the high-level data (for you to think about), and there are a lot of deeper interpretations and conclusions that can be made beyond what I’ve discussed here. Be sure to follow me @Yates_in_the_Backcountry, @PrecisionCutArchery, and @EastonArchery on Instagram as we continue to release more results, draw deeper conclusions, and give our own personal recommendations and interpretations of these results. I am working on some YouTube content with results, as well, which I will have on my YouTube channel, Yates in the Backcountry.

To close, I just want to give another shoutout and thank you to Tristan at Precision Cut Archery, Easton Archery, Black Ovis, and Archery Sound Lab for helping me bring this study about. It takes one person to have an idea, but a solid team to bring about a study of this magnitude. I also want to thank Hoyt for donating bows and a high-speed camera, and for Spot Hogg and Hamskea for supplying sights and arrow rests. We’ve only scratched the surface as far as things to learn and explore, and I cannot wait to continue this effort for years into the future.

For the raw data, statistics, sight tape comparisons resulting from the study results, and methods, please see the Precision Cut Archery Website.

See James’ YouTube channel for a video overview of these results.